High performance machine tool spindle bearing development reference

One of the main units affecting the performance of machine tools, and spindle bearings play a key role. Here are three kinds of spindle bearings developed.

One of the main units affecting the performance of machine tools, and spindle bearings play a key role. Here are three kinds of spindle bearings developed.

he higher the axial bearing spindle bearing capacity.

How to use spindle bearings to prolong their life and bring us greater benefits? Follow XEZ to find out!

For high speed bearings, the grease we chose should have two features: low temperature rising and long service life.

Considering the ambient temperature of 40℃, the maximum operating temperature of the motor should not exceed 120/130℃. The maximum allowable bearing temperature is 95 degrees.

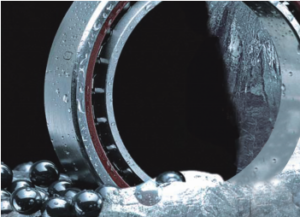

The inner and outer rings and rolling body of rolling bearings should have high hardness and contact fatigue strength, good wear resistance and impact toughness.

The shaft parts of machine tools, especially the spindle bearings, are generally assembled into a body with thrust ball bearings, and rotate at a very high speed, sometimes producing very high heat.

machine, engraving machine must start a major part of the operation, engraving machine spindle is often a problem is easy to bad bearings, some spindle bearings with less than a few months are broken, there are many reasons for the problem.

Machine tool spindle bearing is the spindle bearing of precision machine tools and similar equipment, which can guarantee the working accuracy and performance of precision machine tools.

Machine tool spindle bearings are commonly used in five categories: deep groove ball bearings, angular contact ball bearings, two-way thrust angular contact ball bearings, double row cylindrical roller bearings, tapered roller bearings.

+8618662869458 WhatsApp us