XEZ has been in research and manufacturing of turbocharger bearings for more than 20 years. We have developed many models especially for turbochargers, such as HP5.218, HP60G01, HP1028G03, HP0822G02, HP0822G03, HP0822G07, HP1028G03, HP1028G05, HP1335G01 etc…

| Shaft Diameter | 6-13mm |

|---|---|

| Housing ID | 18-34.8mm |

| Height | 34.2-64.08mm |

| Ball Material | Ceramic Balls |

| ABEC Rating | ABEC9 (P2), ABEC7 (P4) |

| Application | GT28, GT30, GT35, GT40, GT42R, GT45R etc… |

| Model | HP0822G07, HP1028G03, HP1028G05, HP1335G01, HP5.218G34.2, HP60G01 |

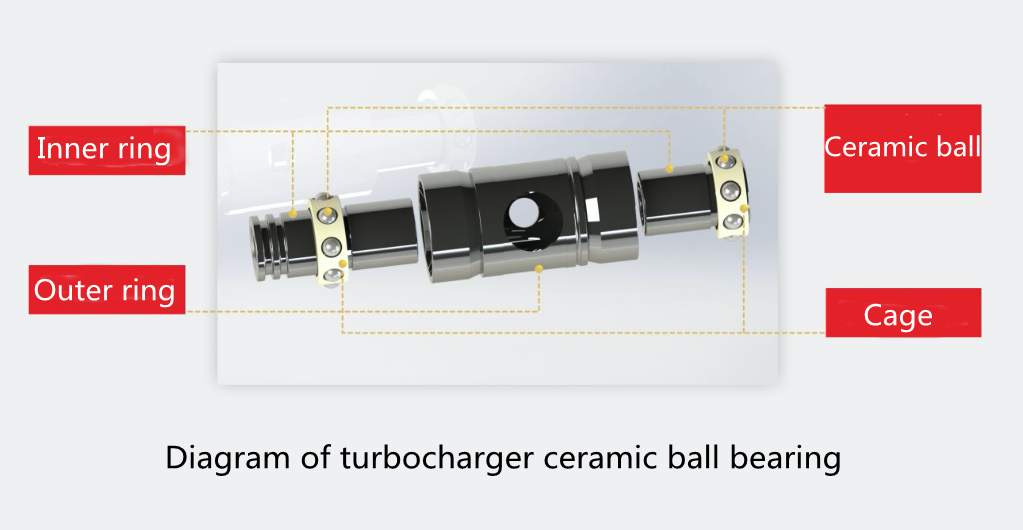

Turbo Bearing Advantage:

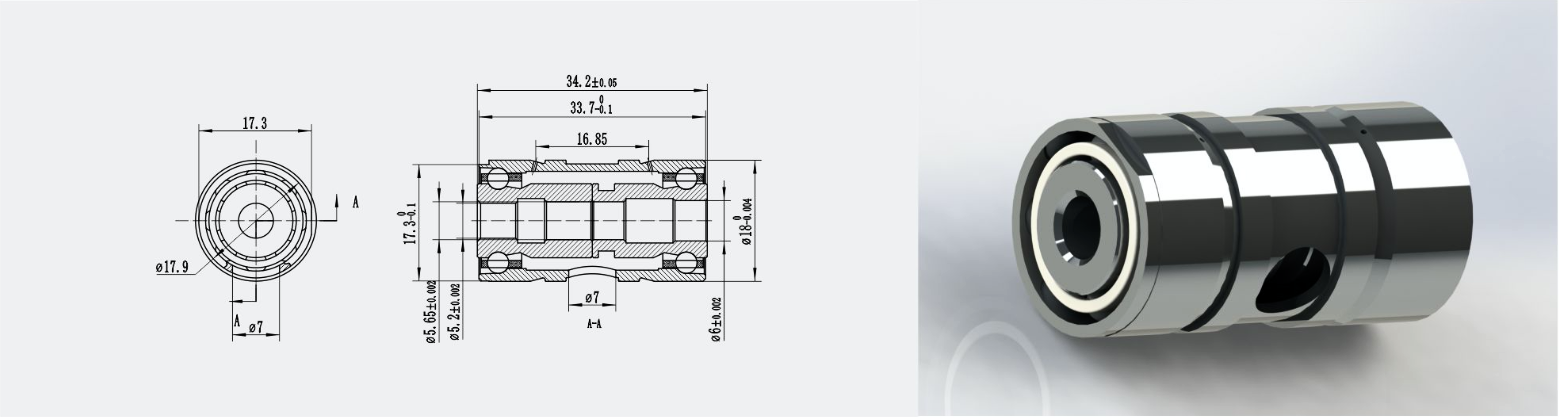

HP5.218G34.2 Inner range: 6mm, Outer range: 18mm, Height: 34.2mm

Apply to GT17/GT20/GT25 Cage is optional:PEEK, Brass, Special metal cage

Basically, the outside diameter step is used for positioning. If there are other positioning methods, please consult us

Limit speed 180000r/m; limiting temperature 600 ℃

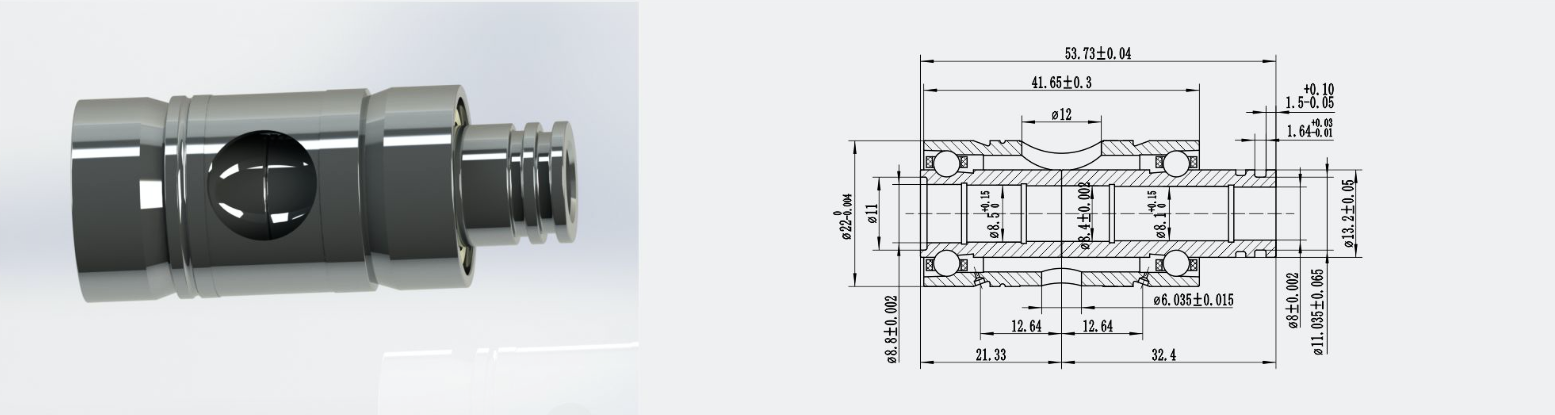

HP60G01 Inner range: 8mm, Outer range: 22mm, Height: 53.73mm

Apply to GT25R/GT28R/GT30R/GT35R Cage is optional:PEEK, Brass, Special metal cage

The basic model is positioned with a 6mm positioning pin. If there are other positioning methods, please consult us

Limit speed 150000r/m; limiting temperature 600 ℃

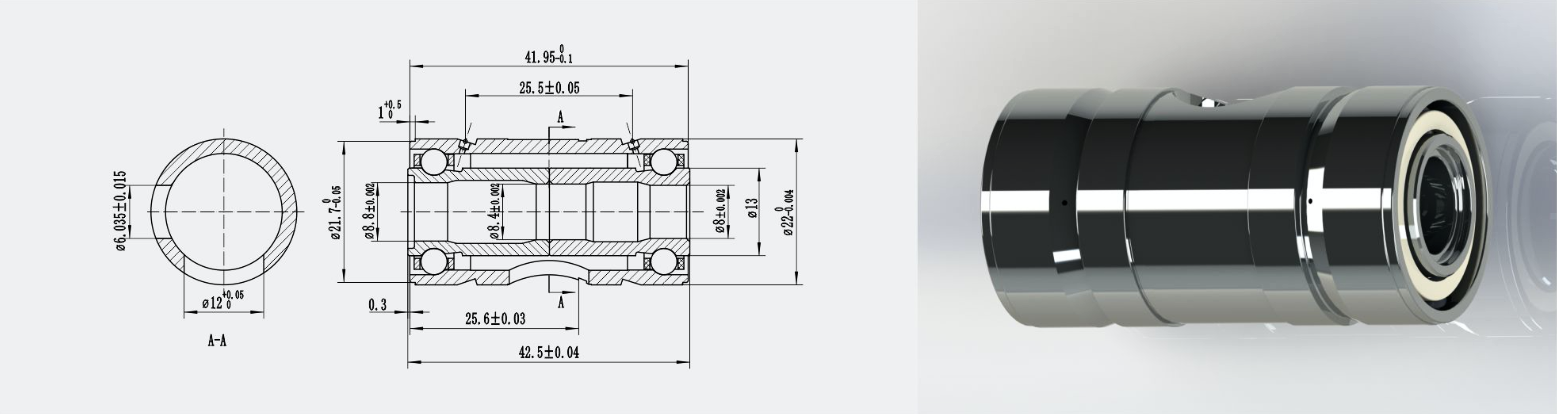

HP0822G07 Inner range: 8mm, Outer range: 22mm, Height: 41.95mm

Apply to GT25R/GT28R/GT30R/GT35R Cage is optional:PEEK, Brass, Special metal cage

The basic model is positioned with a 6mm positioning pin. If there are other positioning methods, please consult us

Limit speed 150000r/m; limiting temperature 600 ℃

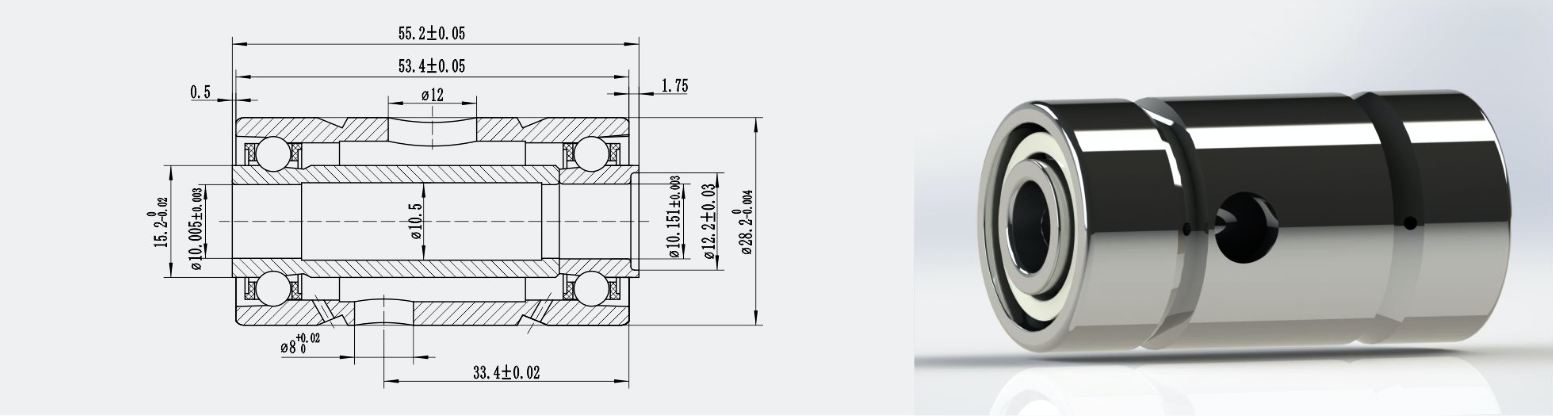

HP1028G03 Inner range: 10mm, Outer range: 28.2mm, Height: 55.2mm

Apply to GTX37/GTX40/GTX42/GTX45 Cage is optional:PEEK, Brass, Special metal cage

The basic model is positioned with an 8mm positioning pin. If there are other positioning methods, please consult us

Limit speed 120000r/m; limiting temperature 600 ℃

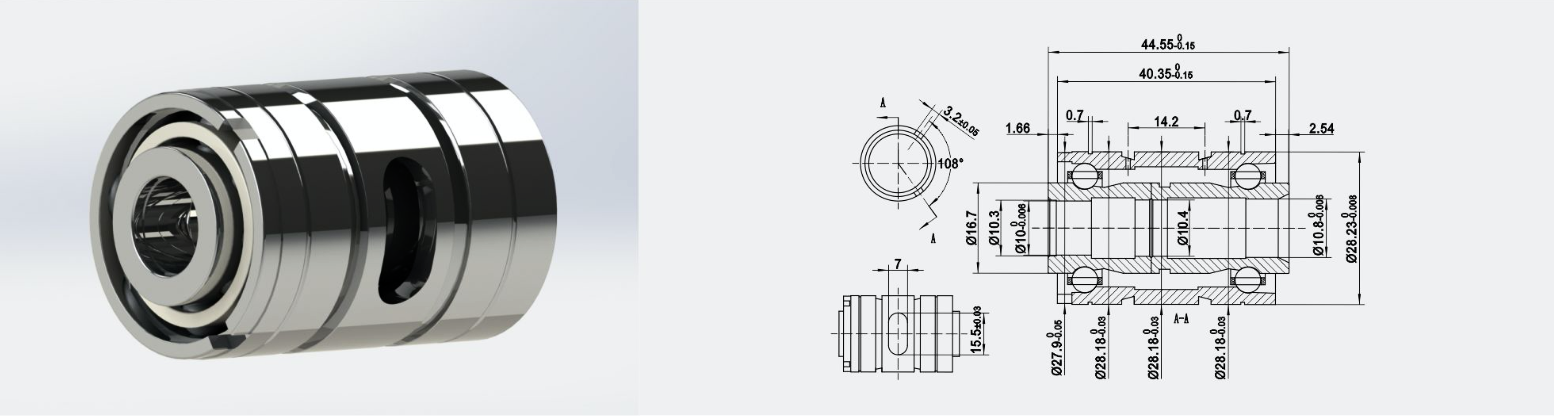

HP1028G05 Inner range: 10mm, Outer range: 28.2mm, Height: 44.55mm

Apply to GTX37/GTX40/GTX42/GTX45 Cage is optional:PEEK, Brass, Special metal cage

With two grooves of outer diameter as positioning, the oil outlet is a 1-word hole

Limit speed 100000r/m; limiting temperature 600 ℃

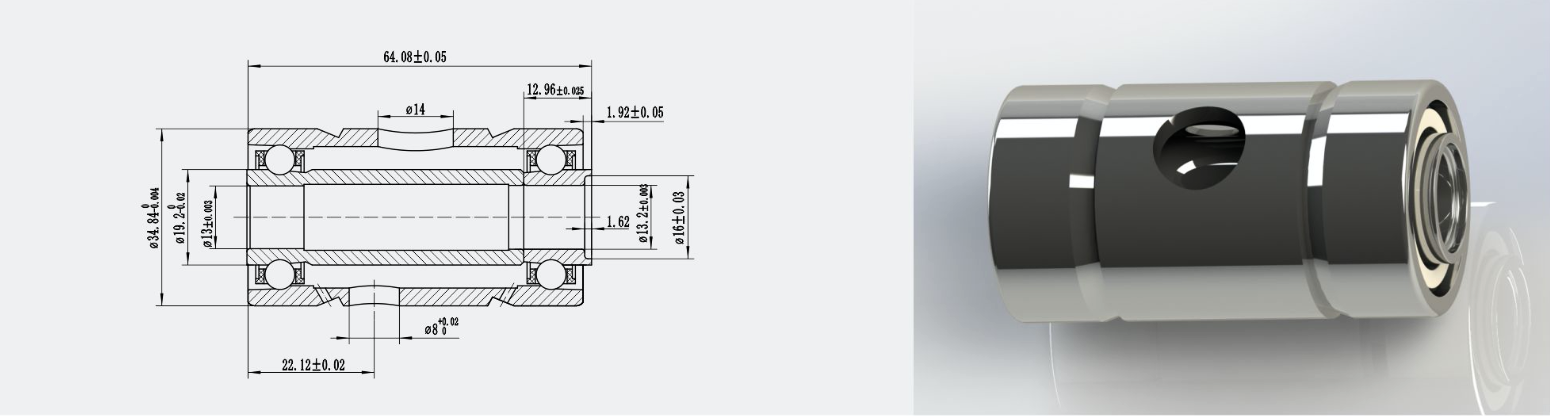

HP1335G01 Inner range: 13mm, Outer range: 34.8mm, Height: 64.08mm

Apply to GTX42/GTX45 Cage is optional:PEEK, Brass, Special metal cage

The basic model is positioned with an 8mm positioning pin. If there are other positioning methods, please consult us

Limit speed 80000r/m; limiting temperature 600 ℃

A great opportunity for us to get up close communication with the giants of the turbocharger industry Garrett. Chinese engineering team regarding the ball bearing turbochargers. ceramic ball bearing turbocharger will be the worldwide trend in the coming future.

Except for Turbocharger Ceramic Ball Bearings, XEZ also supplies other precision ball bearings, range from 6-150mm, please contact our sales team for a sample or quotation.

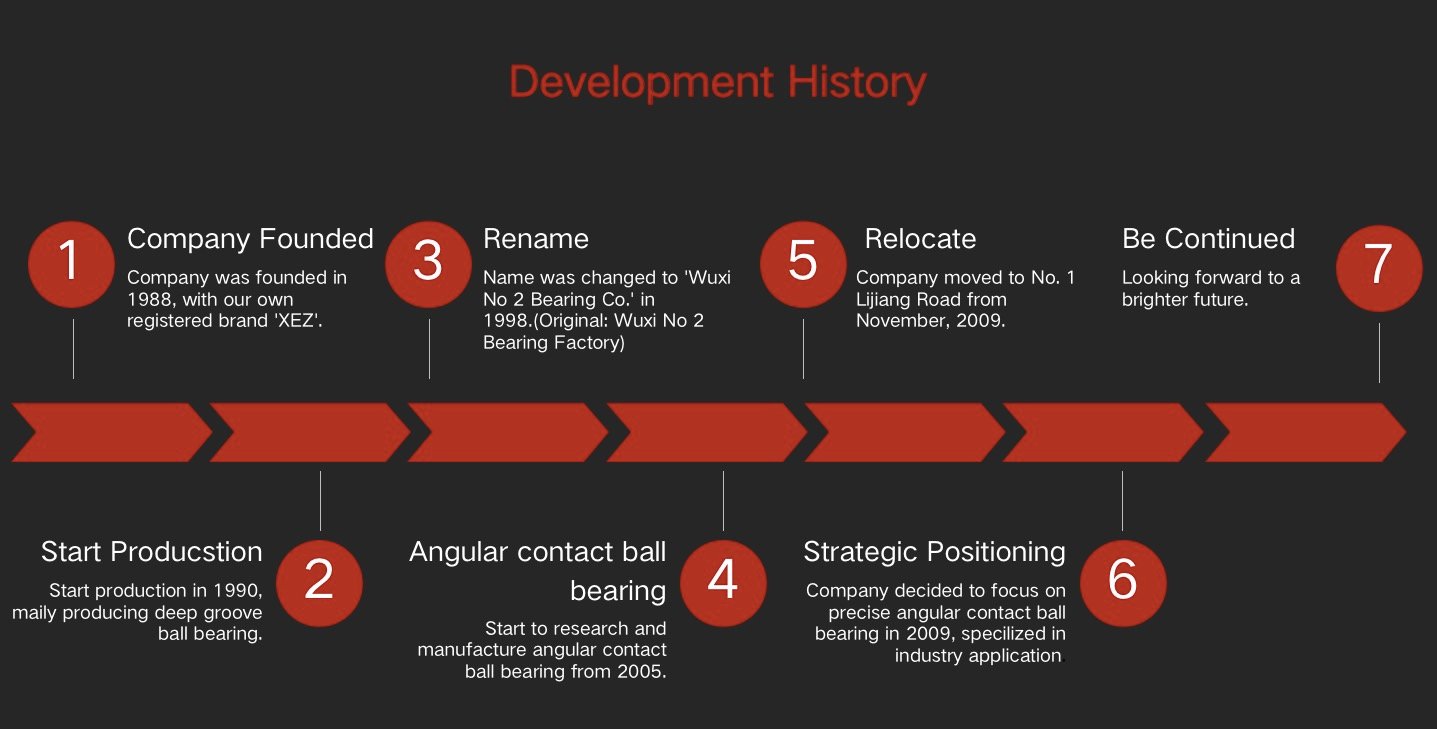

Since its establishment in 1988, XEZ has been a private Sci-Tech enterprise, engaging in the production of high-precision bearing. Currently, XEZ mainly produces precision angular contact ball bearing, deep groove ball bearing, and double row cylindrical roller bearing, which are mainly applied to CNC machine tool spindle, turbocharger, vacuum pump, and other precision machinery.

XEZ factory occupied area 29001㎡, has more than 340 staff.

Annual value of production: 43,000,000USD.

More than 60 production lines for precision ball bearing.

Main Equipment Deep groove ball bearing: 27 lines; Angular contact ball bearing: 20 lines

Parallel surface grinder: 9 sets, centerless grinder: 9 sets Auto inner core grinder: 50 sets, auto inner groove grinder: 50 sets High precise flat grinder: 10 sets Inner/outer groove superfinishing machine: 115 sets Automatic grease injection and capping machine: 27 sets Bearing testing equipment: 10 sets

Highly precision bearings must be made through highly precision manufacuring equipments. Compared with normal company, we have precise calculation whether the equipment can meet the precision requirmeents. We are good at precisely reforming the grinding machine.

Strictly carry out the inspection process, totally 54 manufacturing processes, 20 inspection processes, remove all the defective bearings.

Quality management process: APQP: Advanced Product Quality Planning

SPC: Statistical Process Control

MSA: Measurement Systems Analysis

FMEA: Failure Mode and Effects Analysis

PPAP: Production Part Approval Process

+8618662869458 WhatsApp us

We will contact you within 1 working day, please pay attention to the email with the suffix “sales2@sxz-bearing.cn”.