Keywords: Spindle bearings

The connection of each component of the motorized spindle is very close. If there is component damage, it will affect the operation condition of the entire motorized spindle. So to ensure that the motorized spindle can work normally, we should find that the parts are damaged and replace the motorized spindle parts in time.

If the spindle bearing is damaged, how to replace the spindle bearing? The following small series will briefly introduce the disassembly and installation methods of motorized spindle bearings.

Use of motorized spindle bearings

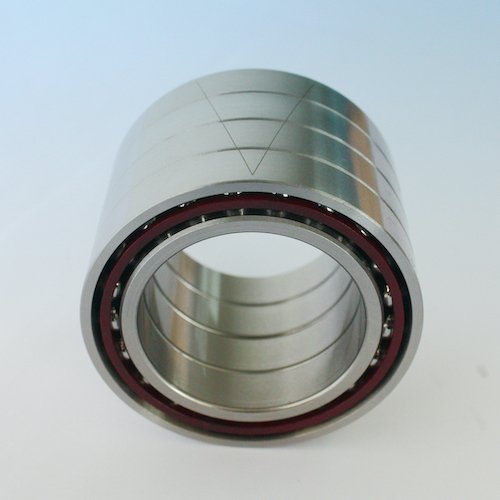

It is recommended that you: use the motorized spindle bearing that has been configured and install it according to the “V” mark on the bearing surface. Note: the spacer used with the motorized spindle should also be of the right size.

Motor spindle bearing cleaning

When cleaning the motorized spindle bearing, the jacket slope of the bearing is downward, or the inner sleeve slope is rotated upward for cleaning. The bearing should be cleaned at least twice, and the upper and lower positions of the motorized spindle bearing can not be misplaced.

Lubrication of spindle bearings

Before installing the motorized spindle bearing, the bearing and the inner hole of the shaft shell and the spindle of the motorized spindle should be lubricated with lubricating oil first. One is to facilitate installation and the other is to ensure the lubrication of the bearing at the beginning of the motorized spindle. Note: the lubricating oil must use the special lubricating oil for the motorized spindle.

Installation of spindle bearings

When installing motorized spindle bearings, the rear end bearings should be installed first. The nut is tightened, the spring is fixed on the bearing seat with butter, and the spring gland cannot be put in the wrong position.

Then assemble the front bearing, fix the front end cover and prepress the bearing jacket (special sleeve should be used for assembling the bearing, which is processed by nylon rod car, and the shape is as follows: D is less than the outer diameter of the bearing, and D is greater than the inner diameter of the bearing).

Tighten the front nut and install the front and rear end caps. When installing the rear end cover, attention should be paid to the position of the air inlet, the sealing ring of the air inlet, the water inlet and the water outlet should be intact and placed in the correct position.

Check whether the spindle bearing is installed in place

After the electric spindle is installed, check whether the spindle is installed in place (push the spindle forward forcefully with a wrench, the spindle will move forward, let go will immediately bounce back.